Simufact Engineering, an MSC Software company and expert in manufacturing process simulation, has announced the launch of Simufact Additive, a ground-breaking new software solution for the simulation of metal additive manufacturing processes.

MSC Software 旗下公司和制造工艺仿真专家 Simufact Engineering 宣布推出 Simufact Additive,这是一款用于金属增材制造工艺仿真的开创性新软件解决方案。

Simufact Additive is a powerful and scalable process simulation environment for ‘right first time’ optimization of laser powder bed fusion processes. Features include simulation of all the key AM process steps starting with ‘printing’ of the part; followed by heat treatment, cutting the part off the build plate and removal of support structures, plus heat and pressure combined processes (HIP). The initial release of Simufact Additive will predict the final distortion and residual stresses of metal 3D printed parts; future functional enhancements will introduce additional features.

Simufact Additive 是一个功能强大且可扩展的工艺仿真环境,用于“一次成功”优化激光粉末床熔融工艺。功能包括模拟所有关键的增材制造工艺步骤,从零件的“打印”开始;然后进行热处理,从构建板上切下部件并移除支撑结构,再加上热压联合工艺 (HIP)。Simufact Additive 的初始版本将预测金属 3D 打印部件的最终变形和残余应力;未来的功能增强将引入其他功能。

The modelling is carried out using CAD data in an innovative and newly developed Graphical User Interface (GUI) environment aligned with the real process work flow. Simufact Additive offers an intuitive approach which starts with defining the general process by determining the part and support components through to definition of manufacturing parameters up to the analysis settings and ultimate results. The software helps to compensate the distortion, minimize residual stresses and optimize the process parameters.

建模是在与实际工艺工作流程保持一致的创新且新开发的图形用户界面 (GUI) 环境中使用 CAD 数据进行的。Simufact Additive 提供了一种直观的方法,从定义一般流程开始,确定零件和支撑组件,到定义制造参数,再到分析设置和最终结果。该软件有助于补偿变形,最大限度地减少残余应力并优化工艺参数。

The concept behind the software is that it lays the foundation for a wide variability and scalability through different levels of details. This includes both a fast mechanical method for the prediction of distortion and residual stresses up to a fully thermo-mechanically coupled transient analysis which will be released soon. This will determine the temperature history and derived properties like the microstructure. The properties of the final part are available for a subsequent structural simulations.

该软件背后的概念是,它通过不同级别的细节为广泛的可变性和可扩展性奠定了基础。这包括用于预测变形和残余应力的快速机械方法,以及即将发布的完全热机械耦合瞬态分析。这将确定温度历史和衍生属性,如微观结构。最终零件的属性可用于后续的结构模拟。

New Graphical User Interface (GUI) concept for AM Modelling

用于增材制造建模的新图形用户界面 (GUI) 概念

Simufact Additive comes with an intuitive and user-friendly GUI. The flexible GUI concept allows machine and application-specific dialogs aligned with the real process work flow. A meshing capability is included for the automatic and rapid discretization of even large and complex structures of any shape. The GUI is laid out to smoothly handle these meshes that can readily reach more than a million elements.

Simufact Additive 带有直观且用户友好的 GUI。灵活的 GUI 概念允许机器和应用程序特定的对话框与实际过程工作流程保持一致。包括网格划分功能,用于自动快速离散化任何形状的大型复杂结构。GUI 的布局是为了顺利处理这些可以轻松访问超过 100 万个单元的网格。

Collaboration with 3D printing machine supplier

与 3D 打印机供应商合作

Renishaw plc, a leading manufacturer of advanced metal AM systems, is the first 3D printing machine vendor to collaborate with Simufact in the common goal of an integrated approach. The aim is a fully simulation based optimization leading to the best quality build file. Initially, Renishaw’s QuantAM build preparation software will be coupled with Simufact process simulation software and enable data exchange, using QuantAM’s open API (application programming interface). The next step is to automatically set-up a simulation based on the build information and in return to display the simulation results in Renishaw’s QuantAM build preparation software. The first results of this collaboration will be published and showcased at the major European additive manufacturing show, Formnext 2016, Frankfurt, this November.

雷尼绍公司是先进金属增材制造系统的领先制造商,是第一家与Simufact合作的3D打印机供应商,共同目标是采用集成方法。目标是完全基于仿真的优化,从而获得最高质量的构建文件。最初,雷尼绍的QuantAM建模准备软件将与Simufact过程模拟软件相结合,并使用QuantAM的开放式API(应用程序编程接口)实现数据交换。下一步是根据建模信息自动设置仿真,并在雷尼绍的QuantAM建模准备软件中显示仿真结果。此次合作的首批成果将于今年 11 月在法兰克福举行的欧洲大型增材制造展 Formnext 2016 上发布和展示。

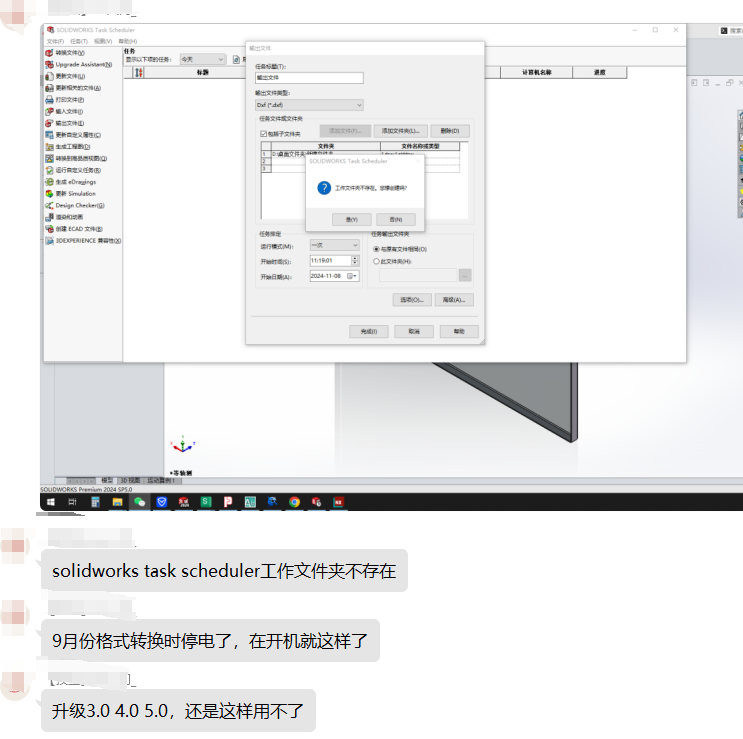

下载地址:

扫描下方二维码关注并后台回复“MSC2024”,获取种子文件下载链接!

欢迎访问https://xmaker.cn/ 创客者V2.0网站获得更多CAX内容

暂无评论内容